“Space age” materials such as titanium, special alloys and polymers, have made their entry into the firearms field, including the very traditionalist field of revolvers, but may require special attention, sometimes very special, in order to not to cause problems. There have been two reasons justifying the use of new materials: the first is purely economical, or rather to manufacture at a lower costs, and the second reason is the attempt to offer the customer something more, at least in the field of ergonomics. With regard to handguns, with this term we do not only mean the convenience of use, with more “natural” and ergonomical shapes, but also those corollary aspects, such as lighter and smaller guns, that make it easier to carry and conceal.

Weapons have always been made of steel, and only after the second world war do we see “light alloys”, branded as having a short life and almost considered an insult to common sense. But at least they were metal. There was a “plastic“ revolution in the 1980s, once again amongst recriminations and apocalyptic prophecies of the end of the handgun world. We already know how this finished: all defense or service weapons currently use synthetic materials for essential components such as the receiver.

After all, if the frame of an automatic handgun does not have to bear enormous stress during shooting, the opposite is true for the revolver; the element is delegated to support all the pressure and forces that are given off. Despite this, since the 1950s, there were versions with light alloy frames of weapons chambered for the .38 Special, a solution that could significantly lower the weight, and give snub nose revolvers for personnel defense a very desirable appearance.

VIDEO: an interesting description from one of our readers

In the race for the lightest possible gun, there had been an attempt to use aluminum alloy for even the cylinder, but with little success, and for decades the “light” versions of small revolvers have used barrels and cylinders made strictly of steel. Of course, research did not stop, and technology has brought into play new materials such as titanium and Scandium light alloys, thanks to which Smith&Wesson has achieved a number of small revolvers built on the “J” frames chambered for the .357 Magnum, weighting just over 300 grams.

These first personal defense handguns were later joined by other highly specialized versions, such as large revolvers in the .44 Magnum caliber (329PD) that, thanks to their light weight, are intended for those who must travel into areas inhabited by wild and dangerous animals.

How was it possible to drastically cut down the weight and keep the option of using high power ammunition open? Of course, by integrating various “science fiction” materials into a single weapon: Scandium light alloy for the frame and the coating of the barrel, titanium for the cylinder and some small parts, an extremely thin tube lined with stainless steel for the barrel.

This “revolution” has spawned from two types of problems, one, which can be easily understood, and a much more insidious and hidden one, relative to the attention required by the new materials.

The first problem is that lightweight weapons that shoot a projectile with great energy will give rise to high recoil and muzzle climb, which, in the revolvers mentioned, can be unbearable.

Fortunately, in many cases less powerful cartridges can be used, leaving “serious” shooting only for “serious” occasions: If you are attacked by a bear or a malicious two-legged animal, the scraping of a finger or a numb hand are insignificant collateral damage.

But a second reason why a weapon that is too light can cause problems is, as mentioned above, that if you do not follow the manufacturer's specific instructions, you may be holding a weapon that becomes only a useless paperweight after a few shots!

Donʼt believe that the weak point is the Scandium science fiction alloy that, with a few atoms of this rare material dispersed in the molecular structure, becomes as strong as steel. The weak point of the chain is none other than the titanium cylinder.

We all think of this metal as the cutting edge of strength and lightness, the use of which has opened new frontiers in many fields. The critical components of aircraft, artificial medical prostheses, endosseous implants, and with regard to weapons, breech shields, pins and strikers are all made of titanium. But in none of these cases must the metal withstand the stress of high-pressure gas and high temperature, as well as the “rain” of debris that causes the firing of a cartridge in the gap between the barrel and cylinder of a revolver. Does it seem impossible that titanium can wear out? We are not the ones who say so: it is clearly stated in the Smith&Wesson manual. Or rather, the letters are clear, but sometimes we don’t read them, and their meaning is not clear and do not shed much light on the whole story.

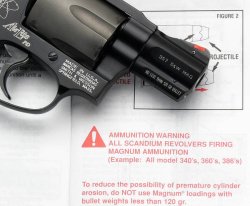

The manual of this lightweight revolver in .357 states: “Warning: Do Not Use Magnum Loadings With Bullet Weights Of Less Than 120 Gr. This Will Reduce The Possibility Of Premature Cylinder Erosion”.

So, even Smith&Wesson states that there is a risk of erosion in titanium cylinders if light bullets are used, but what does it really mean? How "early" is early? And, after how many rounds does this happen: hundreds, thousands, five thousand?

And, what does this wear of the cylinder entail? Does it oxidize, does it scratch, does it melt like ice cream under a hot sun? Can the weapon still be used or, given its lightness, can it not even be used as a paperweight?

In fact, we find various kinds of alloys with different physical and chemical characteristics under the generic name of titanium. The resistance of these various kinds of alloys is similar to the best steels, with a weight of less than half. All are highly resistant to corrosion, or does not rust or degrade over time, although they may form surface layers when combined with the atmosphere (alpha layer).

But these alloys that do not corrode are much less resistant to erosion than steel, since they have a more “porous” structure, and upon shooting, the high temperature gases that carry fragments at very high speed, represent a phenomenal erosive agent, able to creep into the open structure of the material and literally ablate small particles.

To eliminate these problems, the technicians have perfected systems to make the front surface of the cylinder less porous and more resistant. The most popular system involves the “filling” of the interstices of the alloy with carbon atoms.

But, complex technologies are needed to ensure that the carbon penetrates below the surface and attaches to the metal. However, very little, even simple cleaning, is needed to remove it: don't dare use abrasive paste to remove the carbonious burnt propellant deposits, some ammonia-based solvents are also banned and, apparently, metal brushes should also be avoided.

But, if these normal maintenance practices are considered to be “aggressions”, what about the stress induced by the firing of a cartridge, which we know, in the long run, can erode even the best steel (i.e the Flame Cutting problem of revolvers frame)? If you are anxious to know more, youʼre lucky: although in spite of ourselves, we are able to offer a concrete contribution to the knowledge of the erosion phenomena of titanium.

Enter now, the S&W 340 PD revolver, the maximum expression of the Centennial family, chambered in .357 Magnum and weighing only 320 grams, thanks to its Scandium light alloy frame and the titanium cylinder: needless to say, its lightness tempted us and we bought a sample years ago.

The revolver is very portable, concealable, very intriguing and is a perfect example of the “take me often with you and shoot me seldom” category. Seldom, not ever: you need to train with your weapons once in a while, especially those that you carry every day. In the five years of “cohabitation”, we have shot more than five hundred rounds, all .38 Special loads, of which a minimal part with the +P loading. The reason is obvious: shooting something more powerful than a Wad Cutter target load in a weapon that weighs three hundred grams is not a pleasant experience.

Some time ago, but only for “journalistic” reasons, we tried the thrill of two or three full power .357 Magnum cylinders: the trigger guard of the 158-grain Winchester caused a deep wound on our index finger, and that was the end of our leisure use of full power ammunition.

Obviously we were well aware of the vexing problem of recoil. So, why did we purchase a .357 Magnum, which costs considerably more than a .38 Special? The argument we made was that if the weapon was created for the .357, it could withstand a long diet of weaker cartridges. In fact, up to now, we have not had any problems.

Up until one Sunday, when we decide to take pictures of the muzzle flash of a complete series of Black Mamba cartridges in various calibers, and we chose the light Scandium instead of the super heavy Ruger SP101 for the .38 Special and the .357 Magnum loadings.

A warning marking on the right side of the 340 PD frame reminded us what was stated in the manual: “not less than 120-grain”, but we thought that a handful of 110 grainers would not hurt the gun.

Mindful of past experiences, we protected our hands with a glove, loaded a pair of Black Mamba .357 Magnum rounds into the cylinder, set the camera, a blinding flash accompanied the shot and the pictures showed a cascade of sparks between the barrel and the cylinder.

The same thing for the second shot, after which we switched to the milder .38 Special.

After we exited the tunnel, the usual curious people asked to examine “the beast” and so we let various people experience the thrill of the Scandium gun and shot a total of thirty-four .357 Magnum 110-grain rounds.

At the end of the range session, the nasty surprise: the face of the titanium cylinder showed massive signs of erosion, with deep “wounds” between one chamber and the other. So much for the “Premature Erosion Cylinder” that the manufacturer warns about! Already with the first shot, as luckily documented by our photos, the material was literally “blown away” from the surface and igniting; this explains the shower of sparks!

A quick Internet search showed that we were not the first that had experienced this, but we have not found pictures that are as eloquent as the one we made and that illustrate this article. Even though it is obvious that the Internet mainly shows the opinions of those who have had problems, while those who have not had them are part of those who can be called the “silent majority”, it is clear that the use of titanium in revolvers require special attention.

We informed the manufacturer of this. The manufacturer explained that the reason why they do not recommend shooting .357 cartridges with bullets under 120-grain is because the powders used are too fast burning and have the possibility of eroding the face of the titanium cylinder. Fortunately for us the light .38 loads are acceptable. The answer, of course, did not convince us: an e-mail sent to Fiocchi gave us information on the properties of the propellant used, not very different from that of other loads. Thus, the powerful Italian cartridges are not the root of the problem.

And so we’ve wasted an expensive revolver, and all because we did not follow the warnings listed in the manual "by the book": If we happen to use weapons with a titanium cylinder in the future, we promise to thoroughly read the original manual.

The final word is that the user of a firearm MUST ALWAYS read the WHOLE manual, even when said manual contains very obvious warnings along the lines of “do not aim the gun towards things that are not intended to be shot at”, because in that part of the manual is exactly where the warning in regards to the use of loads heavier than 120 grains is located.

To conclude, we would like to relay Smith&Wesson’s reply to us:

“Hi, the reason why we recommend you don't shoot .357 magnums under 120 grain in that gun is because the quick burning powder that is associated with the lighter grain bullets presents the possibility of eroding the face of the titanium cylinder. This only applies to the .357 magnum round, below 120 grain is fine for the .38 special”.

Obviously, these convenient revolves have a more than sufficient duration if we avoid using magnum loads and shooting fifty rounds a year but, as consumers, we would prefer more accurate information from the manufacturer or importer.