But let's start from the very beginning. Horst and I have been loading our own ammunition for dynamic IPSC shooting for over 6 years. In the meantime, we can no longer start at any competition without our own ammunition.

First of all, however, it should be said that there are two main reasons why one makes ammunition oneself and therefore equips old or new cases with a new primer, powder and bullet for this purpose. Either one does this for financial or quality reasons. The components, especially for pistol ammunition, are usually cheaper than factory ammo. And when reloading, you can build cartridges that are precisely adapted to your own requirements and gun's demands. So you can make – for example, much more accurate rifle ammunition – or, in our case, ammo with which we can compete in an IPSC competition.

However, we must again distinguish here that reloading high-precision long range rifle ammunition is really about quality. Each step is performed individually by hand and checked countless times for the smallest deviations.

We, on the other hand, load for quantity. We have two fully automatic Dillon reloading presses that produce between 800 and 1,200 cartridges per hour at the push of a button. It goes without saying that there are sometimes defective cartridges.

So why do we do it then? Why do we reload when precision doesn't matter?

Two reasons:

- The prescribed MAJOR power factor

- Smooth cycling in our redesigned and highly tuned OPEN Race guns.

IPSC: what does MAJOR and OPEN mean?

Now we come to the science of IPSC sport 😉: In the dynamic IPSC discipline there are 6 different divisions, into which the guns used are divided.

PRODUCTION – these are former service pistols like Glocks or sporting pistols that are carried by special forces and are on the Production list, like the CZ Shadow 2. Here there is only a MINOR rating with 9mm.

STANDARD – here it is allowed to tune something that is forbidden in the Production. However, you are not allowed to use red dot sights or compensators. There is a MINOR and MAJOR rating.

In MINOR, 9mm must be fired and a power factor of at least 125 must be achieved. The power factor results from the muzzle velocity and the bullet weight.

In the MAJOR rating, shooters generally use .40 S&W and must achieve a power factor of at least 170.

If you start in the MAJOR rating you get more points for edge hits, which is not only very pleasant, but can often decide between victory and defeat.

In the PRODUCTION and STANDARD divisions, but also in the other divisions such as the CLASSIC (1911s with 10-round magazines), REVOLVER or PRODUCTION OPTICS (production pistols with a red dot sight on the slide), weaker ammunition is usually reloaded, which is more comfortable to shoot and just about achieves the prescribed power factor.

Reloading cartridges and the power factor in the IPSC OPEN Division

In the OPEN division, however, things are quite different. In this division, only magazine length is limited, otherwise almost everything is allowed. These guns therefore have a red dot sight and, among other things, a compensator, in our case even a ported barrel. The compensator basically works like a muzzle brake, only upwards. The gases that flow out of the barrel are deflected upwards. This drastically reduces the gun's muzzle flip. The pistols are "steady" when firing, which means they have hardly any climb. This allows the shooter to shoot a precise follow-up shot more quickly, since the gun never leaves its target.

However, for this to work, the compensator needs gas pressure. A lot of gas pressure.

To be rated MAJOR in the OPEN division, you need a power factor of at least 160, but most OPEN shooters, including us, shoot a much higher power factor. This is because here you load until the pistol "stands still". The compensator has enough gas pressure to compensate for the high recoil and thus to be able to shoot at maximum speed.

So when Horst or I shoot factory ammunition in training, the pistol "flutters", meaning it isn't steady, but has noticeable muzzle flip and we have to shoot slower.

But there is another reason why we reload, and that is function:

A Formula 1 car doesn't run on regular gas, and neither do our race guns. We shoot the .38 SA caliber. This caliber is basically a long 9mm, 9x23 to be exact. In this caliber, there is a difference between Super Auto and Super Comp. Like the 9mm Luger cartridge, the Super Comp does not have a rim which protrudes beyond the case, but a groove. The Super Auto cartridge has a rim, which is more easily engaged by the extractor and thus the pistol has less extraction interference. However, this rim poses the risk of jamming the cartridges in the magazine.

Therefore, we shoot with GECO .38 Super Auto cartridges in training, but we cannot shoot competitions with them, because they have too low a power factor, the pistols do not stand still and there are always feeding problems, since cartridges get "stuck" in the magazine.

So now we know why we need to reload and at what point it might make sense for you.

Into practice: this is how Samantha and Horst load their cartridges for the IPSC OPEN Division

When reloading, either new cases are used or already fired cases are primed, i.e. the fired primer is removed, the case is resized (i.e. brought back to its original shape, since every case deforms slightly when fired), and then a new primer is inserted. This is done either on a single-station press, as in reloading rifle ammunition. Or on multi-station presses that are driven either manually or by a motor. In our case, fortunately, my fiancé and I both shoot in the OPEN division, both with identical Atlas Gunworks pistols and both with .38 Super Comp.

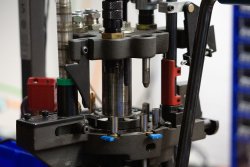

So while Horst operates the reloading press, I check the competition ammunition. For reloading, we use an 8-station Dillon press with a Mark 7 autodrive. The cases are fed automatically and placed on the shell plate. The plate rotates and the case moves one station each cycle. At the first station, the case is primed, removing the old primer. The machine then resizes the case, i.e. brings it back into shape. A new primer is then inserted, powder is poured in, and the case mouth is slightly flared so that the bullet can be inserted in the next step. The bullet is then crimped, i.e. the case mouth is pressed against the bullet again. And a new cartridge is ready. This is the rough sequence, depending on how many stations the press has and which caliber is loaded, steps are combined or repeated individually. Whether cases need to be cleaned beforehand or not depends mostly on the tolerances of the gun and the preferences of the reloader.

My recommendation for anyone who wants to start reloading is to find someone who can to walk you through the basics. You should be clear in advance for what reasons you want to reload: for financial reasons, for quality, or for function. And you should know it's noisy, dirty, and time-consuming. It doesn't work in the living room next to the TV. You need your own room that complies with safety regulations, and you also need patience and a technical understanding of how your own gun and ammunition work.

In addition, a few safety warnings about reloading

It should be clear to everyone that caution is required when handling ammunition and powder.

But it should not be forgotten that the nitrocellulose powder alone can also be dangerous. What is often underestimated, for example, is the danger of an explosion when vacuuming. This is because the brush sparking of the electric motor can cause an ignition. That is why there are special explosion-proof vacuum cleaners.

But caution is also required with the primers. Because these consist of initiating explosive and in contrast to the nitrocellulose powder, which strictly speaking only burns, when heat and pressure arise these can actually explode. Every now and then this happens during primer seating, causing all the primers above it in the primer feed to go off as well. Rarely does this lead to serious injury, but I strongly recommend that everyone wear safety glasses and ear protection, even if it's just music headphones 😉.

Editor's note: the author lives in Austria. Different legal regulations apply there than in other countries. The author's tip to take the first steps with an experienced reloader is nevertheless fully valid.

And finally, of course: every reloader acts on his/her own responsibility! The components are available from almost all major ammunition brands.