The Piotti brothers have always maintained – and rightly so – that one of their strongpoints lies in being able to deal with any type of weapon construction: double barrel, over and under, kipplauf, express, and carbine, are all part of their usual production. Recently, I was able to take a look at a delightful takedown carbine based on a Mauser action with three barrels, which I am going to take another look at for a future article.

Semiautomatic shotguns have always been a source of some perplexity. The semiautomatic is the simplest shotgun to make but also the hardest to fine tune, with the possibility to fire cartridges with extreme weights on both ends of the spectrum, light and heavy.

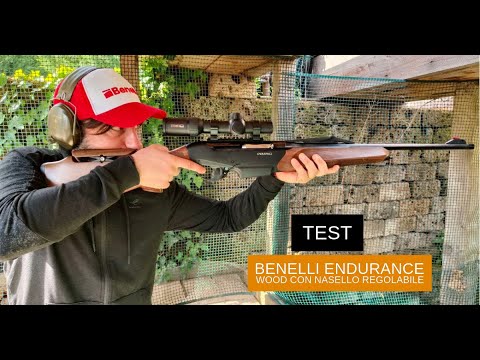

Piotti elegance and Benelli mechanics

Once the weapon has been fine tuned, the simplicity of the construction – which needs no finer adjustments and is limited to the formal expression of its design (a direct consequence of this type of action) – means that any further possible intervention should be quite limited.

The trigger action is one type only. There are no possibilities to use single- or double- trigger actions, or to choose from sequential or selective single trigger.

In addition, those who buy a semiautomatic shotgun don’t always know how to tell the difference between manual and laser checkering. It seems, therefore, that possible interventions to make an industrial product into a fine shotgun are quite limited, but this is not really the case.

The Piottis have come to an agreement with Benelli, a manufacturer identified with the inertia operating concept.

They receive unfinished parts from Benelli, which do in any case come from the higher-end series, i.e. the Executive with martensitic stainless steel receiver. These parts are then given their finishes and functionally improved by Piotti. The Benelli mechanics are considered the most reliable ones for a smooth bore semiautomatic shotgun and therefore the starting base for these shotguns is of the outmost quality.

Piotti semiautomatic shotgun – technical features

One obvious intervention has been carried out on the stock.

They say that it's the shotgun that fires but it's the stock that hits the mark, and this is definitely a well-founded assertion.

The stock of the Piotti semiautomatic is made to measure for the individual customer, in house. As far as it is possible to intervene on an industrially made stock using shims and wedges to improve the length and comb, a real made-to-measure stock is something completely different. Trap shooters are well aware of this, for example, and dedicate meticulous attention to their stock.

It goes without saying that with a bespoke stock, there is no point to a indicate what we regularly find in technical features: the overall length of the weapon.

This in fact varies according to the length of the stock and barrel.

When it comes to stock material, we should remember that Piotti was among the first – forty years ago – to go to Turkey in search of prime quality briar woods.

Dordogne walnut had been finished for quite a while, and European walnut did not provide enough boards and there was no way to get Georgian walnut, since Georgia was still part of the USSR, so Turkey became a new source for wood.

All of the walnut purchased was seasoned in the factory, and it still is, for a period of eight to ten years. Besides the quality of the wood and the cutting to size, there is another thing that makes the difference: the point of contact between the stock and the receiver.

The shaping of the steel and correspondingly, on the wood, is more than a simple aesthetic feature, it drastically increases the contact surface between wood and steel, with obvious benefits for the overall durability of the assembled item.

The shape of the receiver top adds a touch of refined elegance.

It is skilfully created by carving, an operation that is now only carried out by few artisans. At the same time, it forms a kind of housing for the breech, where the new safety has been placed, making it much more practical and easy to use than the traditional cross-bolt safety used on industrially manufactured weapons.

Greener said that out of the almost two hundred parts that make up a shotgun – he was referring to the double barrel but what he said applies elsewhere - the two most important are the barrels.

And this applies even when there is just one barrel, as on the semiautomatic. Piotti’s semiautomatic in fact has a Piotti barrel, made entirely in house and finished as befits a fine shotgun.

Making the barrel in house means that the customer can choose the required length, have a perfect choke or choose interchangeable chokes, and also to select the chamber length: 12/65, 12/70 and 12/76 are the three chamberings available.

And as far as the Benelli barrels are concerned, these are made through cold forging and subjected to cryogenic process. There is no doubt when it comes to quality that the barrel forged in special steel, with a honed bore using a slow process that provides excellent results, i.e. with a lead honing and fine sanding, its quality is not compatible with the industrial costs of mass production.

Stock, barrel and safety are not the only areas in which Piotti has intervened. For example, the bolt lever can be folded. And all of the parts have been polished with the finest possible crocus cloth. These interventions may not be obvious, but they do not escape the careful eye.

They are above all interventions that make the difference between a mass-produced shotgun and a fine one.

Lastly comes the engraving, which is executed according to the instructions of the customer and can be extended to the part over the action, where the barrel is fitted.

Fine engravers work for Piotti and they are able to meet practically any requirement, as befits those who are used to working only to order. Of course, quality does not come free of charge and the Piotti semiautomatic comes at a retail price that starts from 9,000 euro.

For further information please click here.