In our recent visit to HIKMICRO Tech’s headquarters in Huangzhou, China, the most interesting experience has been – without any doubt – the visit to the Chinese giant’s manufacturing facilities and assembly lines for the opto-electronic devices. This is where most, if not all, HIKMICRO’s hunting thermal imaging optics are built. Our Factory Tour started at the parent company, Chinese Tech Giant HIKVISION, in which all invited guests and members of the media were introduced to all the different technology fields covered by the holding, and that also account for the diversified know-how that contribute to successful products.

The showroom – more like an actual Science Exhibition really – showcased all the company’s technological achievements as we mentioned in our previous article, and also is a good explanation on how it was possible for this brand to storm the market in such short time. Just to put this into perspective, having in-house development and production capacity for silicon chip level sensor, memory and ASIC manufacturing, alongside expertise in AI and software engineering, optical technology, mechanical and materials engineering and many, many more, is an immense advantage as it became clear in our visit. In the showroom, a small hand-held object caught our eye: one of the first Thermal Imagers tools for temperature and thermographic analysis, a forerunner of the technology at the core of the sports and hunting optics we use today.

After the showroom, we moved to the HIKMICRO Research and Development building and Sensor Fab complex, where most of the new products are designed, and also where Silicon wafers are turned into Vanadium Oxide thermoelectric Focal Planar Array image sensors using advanced MEMS and WLP technologies. And, obviously, we were not allowed to film or take any pictures of these facilities, and even the clean rooms where the actual sensors were made were physically in another building! We could take glimpses of what was going on inside the amber light bathed rooms only through remote cameras and far away windows. However, it was very informative and extremely interesting.

Our next visit was much more "hands on" – the final assembly lines of the hunting and sports optics thermal imaging products. We were actually impressed by the scale of the spaces in which the assembly lines are located; the factories are built in such a way that these spaces can be reconfigured in a very limited amount of time to accommodate entirely different assembly needs and products. While everything seemed highly effective, the unbridled idea and philosophy that just popped in my mind was "it works like a field hospital!".

Most of the materials and parts are all placed in shelving mounted on wheels, workstations are easily movable but above all the small, almost portable nature of the pressurized clean rooms in which the most critical assembly was carried out only reinforced my vision, and I can just imagine how easily the assembly lines could be moved and rearranged, following, i.e. the introduction of a completely new product to be assembled.

Obviously, assets such as environmental testing rooms and labs are permanent, but not exclusive to the specific hunters and sports optic production, and just to prove this right, side by side to the sports optics lines, gimbal mounted multispectral cameras and surveillance devices were built in similar assembly lines.

Most of the logistics for the needed assemblies and parts to be built into final products are automated and carried out by small, AI-driven load bearing robots – also in-house built! Corridors allowed for fast-track reserved lanes in which an actual traffic of these robots carried parts, assemblies and finished products from one part of the factory to the other.

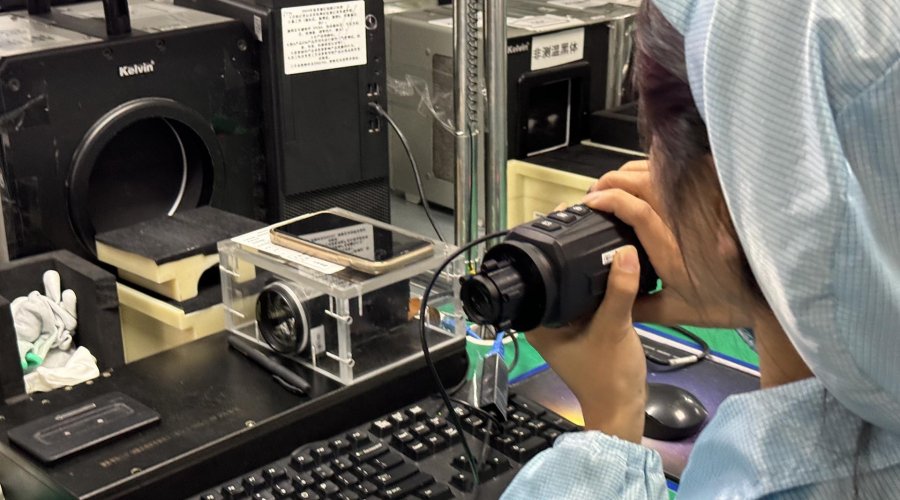

Some of the finished products undergo additional testing depending on the end use – for example, riflescopes and front optics attachments are impact and vibration tested on an hydraulic driven sled with one degree of freedom, simulating harsh firearm recoil; the optics are mounted on the test fixture using standard Picatinny rails. Other tests involve extreme cold and hot temperature rating in climate rooms, dust and water resistance, and performance compliancy tests.

During our visit we also had the chance to look at some upcoming products that are expected to be released soon, some in the immediate future, some other at SHOT/IWA 2025, although we cannot still talk about these exciting new products due to the mandatory NDA we had to sign.

But please subscribe and follow all4shooters.com and all4hunters.com to avoid missing any new product release and field test!

Disclaimer: thermal imaging riflescopes and clip-on devices that are designed to be used on a firearm may be restricted in your area or region.

For additional information: https://www.hikmicrotech.com/en/