A Russian perspective

The so-called “Balanced action” saw the light following several attempts to decrease recoil of rapid-firing weapons, in which rearward and forward movement parts such as bolt group created additional forces that tend to disrupt aiming efforts. This is especially true if the bolt group hits the receiver at the rearwards end of its recoiling movement.

A classic example of a gun that is known for high impact velocities of its moving parts is the Kalashnikov AK-type rifle, and all its derivatives. The mass of the moving bolt group of an AKM rifle tops about 520 grams, and under normal conditions it hits the rear end of the receiver with velocity of 3.5-4 m/s. This creates additional recoil impulse of about 2 kg*m/s, which adds another 20% to overall recoil impulse generated by the bullet and powder gases. This high moving parts impulse was indeed intentionally achieved upon engineering, as it increases the overall reliability of the gun, but in this case reliability comes at the price of decreased accuracy.

Soviet R&D programs attempting to decrease negative effect of moving parts got impulse in late 1960s, when researcher Peter Tkachev from the TsNIITochMash research institute introduced the new concept of “balanced impulse of recoiling parts”.

According to this concept, recoil impulse of the moving parts can be neutralized by the counter-recoil impulse of additional part whose weight is about the same as the bolt group's, which should move synchronously in an opposite direction.

In the 1970s, Sovied engineers developed several “balanced action” assault rifles using the then-new 5.45x39 ammunition. These included the AL-4M, developed at the Izhevsk Mechanical Plant, and the SA-006, developed at the Kovrov plant. The latter prototype, designed by A.S. Konstantinov, became the main rival to the new 5.45x39mm-caliber Kalashnikov rifle in the 1974 Soviet army trials. In fact, the SA-006 outperformed the would-be AK-74 in terms of hit probability, especially when firing from unsupported and off-hand positions or on the move. It also performed adequately well in terms of reliability and durability.

Despite these results, the Soviet Armed Forces adopted the Kalashnikov design, which was simpler, cheaper and already familiar to the industry and troops. The main reason behind this “retrograde” decision was that the Soviet establishment wanted to get a new small caliber rifle into service as quickly as possible in order to bridge the gap between the Soviet and the U.S. Forces in terms of small arms fire effectiveness. Apparently, the AK-74 was originally considered as a stop-gap measure only, as in late '70s several R&D programs were well underway to achieve marked superiority of individual assault rifle fire effectiveness over existing designs such as the AK-74 and M16A1 themselves.

These R&D programs extensively pursued and tested the “balanced action” principle, among many others.

As a result of these programs, the Soviet (and later, Russian) Armed Forces held the now famous “Abakan” trials that saw several balanced-action rifles being tested.

The trial was won well into the 1990s by a system based on a different approach, the Nikonov AN-94 assault rifle. Despite this apparent failure at the “Abakan” trials, two major small arms development and manufacturing centers continued their work on balanced action systems.

Those were the IZHMASH factory − whose AKB line of experimental assault rifles was designed by Mikhail Timofe'evich Kalashnikov's son, Viktor Kalashnikov − and the Kovrov Mechanical Plant (KMZ), whose designer Sergey Korshakov developed the AEK-971 assault rifle design.

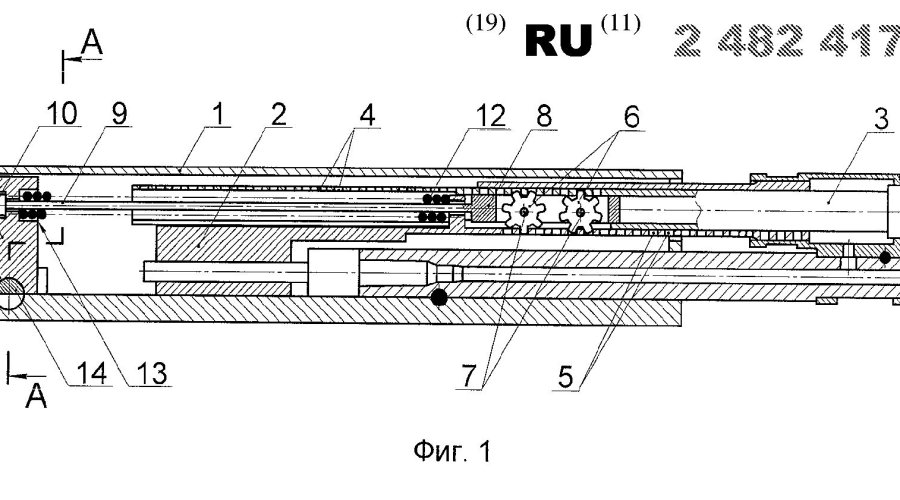

Despite formal adoption, AN-94 turned out to be a practical failure, with relatively few made and issued to Russian Armed Forces during late 1990s before it production stopped for a variety of reasons. In the meantime, IZHMASH evolved balanced action rifle prototypes into the AK-107 and AK-108 production-grade rifles chambered for the 5,45x39mm, 7,62x39mm and 5,56x45mm calibers, while KMZ continued to refine its 5,45mm AEK-971 and its 7,62x39mm caliber version, known as the AEK-973.

In the early 2000s, the KMZ plant delivered an unspecified, but relatively small number of AEK-971 rifles to Russian Internal Affairs Ministry (MVD) Spetsnaz troops, and, apparently, those elite units liked AEK-971 more than AN-94 or AK-74M.

As a result, KMZ continued development of the AEK line until 2006; after that, when KMZ closed down its military production lines, the AEK-971 related designs, technologies and developments was passed to ZID (the “Degtyarov Mechanical Plant”), itself headquartered in Kovrov.

The successor of the baseline AEK-971 design, initially known as the AEK-971M and later as the A545 (official GRAU index denomination 6P67) was proposed to the ongoing “Ratnik” trials − being held by the Russian Army to find a suitable replacement to the AK/AKM platform − to compete against the updated, but still “unbalanced”, Kalashnikov-based design known as the AK-12. At the same time, limited production of AEK-971 derivatives continues at ZID for élite units of the Russian Law Enforcement community, and IZHMASH (now known as the "Kalashnikov Concern") is currently attempting to create a semi-automatic civilian version of the balanced-action AK-107 assault rifle, known as Saiga Mk-107, mainly aimed to IPSC/3-gun shooters.

Historical origins

As a matter of fact, the origins of balanced action can be traced back several attempts at the creaton of low-recoil firearms, way before World War I. In these attempts, designers tried to compensate for recoil impulse of reciprocating parts of gun mechanism by providing a counter-recoiling weight, mechanically linked to the recoiling group.

The general idea here was to neutralize the additional recoil impulse, generated by heavy bolt groups slamming back and forth in the receiver during every firing cycle. This system would decrease felt recoil and neutralize additional vibrations and off-balancing effect of the moving parts, thus improving accuracy and controllability of full automatic (burst) fire at the cost of increased complexity of the gun.

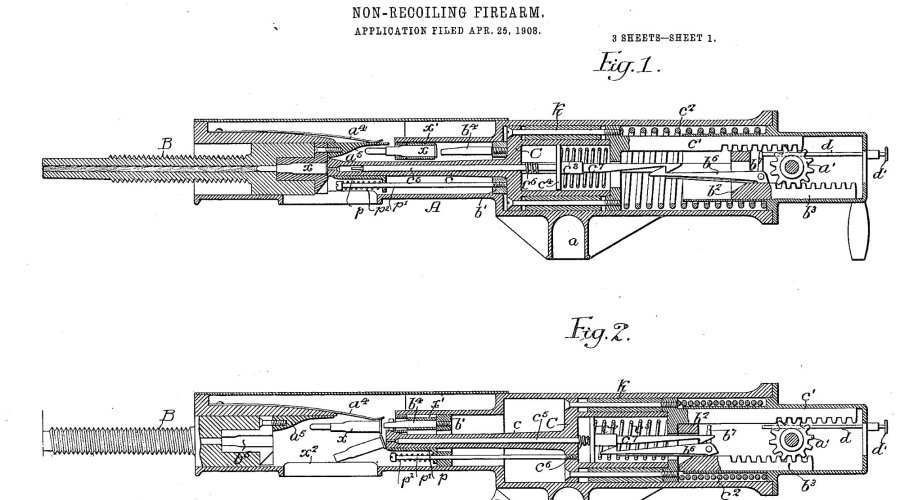

One of the earliest patents, found by the author of this article, dates back to 1908. Designed in UK by Ludwig Mertens and registered in USA as US Patent number 891,778, it is simply titled “Non-recoiling firearm”. In one of its embodiments, Mertens' invention is described as a belt-fed machine gun that has barrel and bolt movable in opposite directions inside a single housing. Movement of the barrel and bolt is synchronized by a rack and pinion system.

In 1920s, American inventor Robert Hudson designed a machine gun in which a massive gas piston moved forward instead of a more traditional rearward direction, in attempt to decrease overall recoil.

In the late 1930s, his system was mature enough to be actually adopted as a 1.1-inch (27mm) automatic anti-aircraft guns for naval use.

Installed in quadruple mounts, Hudson's guns fired at about 110 rounds per minute per gun. Hudson also experimented with smaller caliber guns, including .30 caliber (7.62mm) and .50 caliber (12.7mm) machine guns, but these remained only as prototypes.

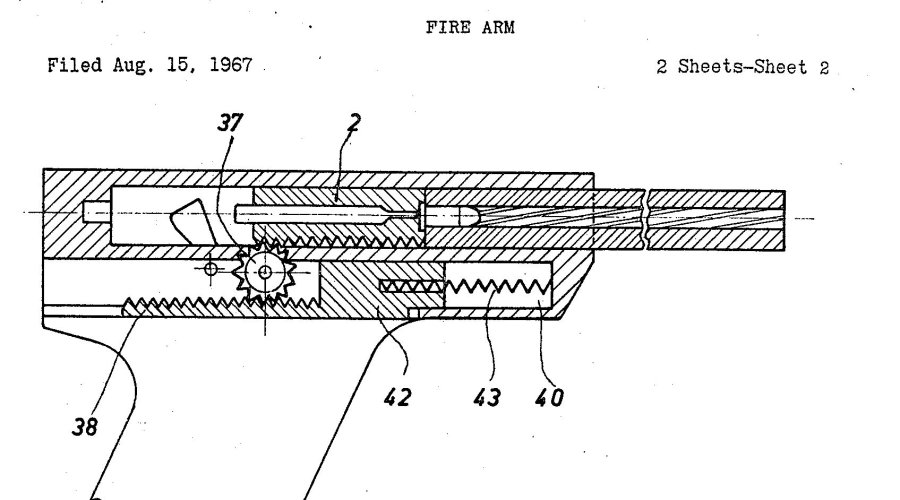

An interesting development of the balanced operation system could also be traced to Switzerland, around the time when Soviets engineers worked on the concept as described above. Edwin Rohr, a designer working for the Swiss-based Hämmerli A.G. gunmaking company, applied in 1966 for a patent that covered several methods to reduce recoil and muzzle flip of a self-loading firearm, more specifically a target pistol. In his patent, Rohr describes a simple small-bore, blowback-operated target pistol, which can be fitted with a counter-balancing weight that cycles in the opposite direction to the slide movement.

Operation of the counter-weight was ensured either by powder gases, driven from the bore through special channels, or via a rack-and-pinion system, very similar in concept (but not in execution) to the system employed in Russian assault rifles.

Rorh received his US patent in 1970, and it is unknown if Petr Tkachev − one of the most important Soviet engineers to work on balanced operation on small arms − was aware of his system or not.

However, we could say with almost 100% certainty that Rohr was not aware of Tkachev work, because, per Soviet customs, all military-related research was conducted under strict secrecy. It is not known if Hämmerli ever produced a prototype target pistol based Rohr’s patent.

Finally, it is worth to note that balanced action principle was also applied − although mostly on a strictly experimental basis − to other classes of firearms, most notably submachine guns.

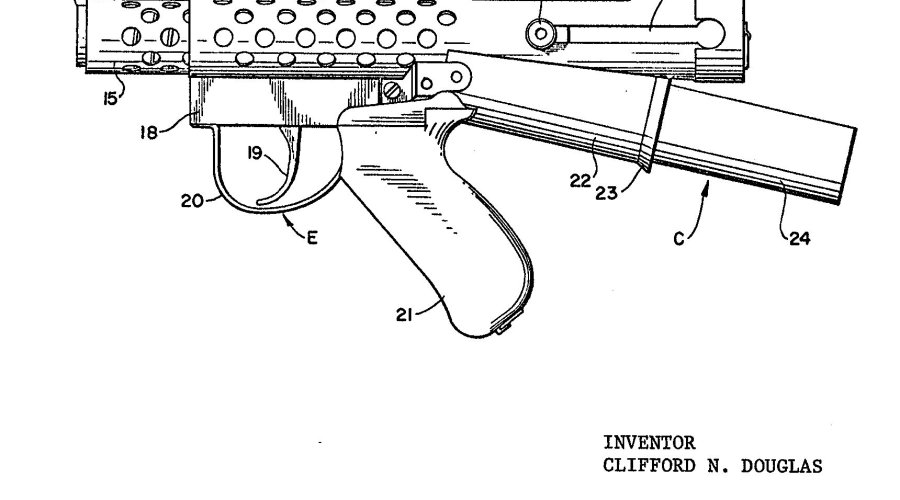

In 1969, Canadian designer Clifford Douglas applied for a patent for a “recoilless firearm”, which, as described, was a compact submachine gun with simple blowback bolt and forward-moving barrel. It is interesting that there was no direct mechanical synchronization between counter-moving barrel and bolt, their only connection being a common spring that pushed them together.

Another unusual feature of the Douglas gun was use of a helical magazine, driven by a gun action rather than a built-in spring.

Apparently, Douglas built some prototypes of his gun, but none were ever adopted by any force. Later on, in the early 2000s, the aforementioned Russian KMZ mechanical plant built a small number of prototype balanced action submachine guns chambered for the 9x19mm caliber.

These submachine guns, known under collective designation of "AEK-918", featured simple blowback operation with counter-balanced weights.

Another approach was adopted by the IZHMASH designers in their PP-27 "Klin-2" submachine gun prototype.

Designed to fire the powerful 7,62x25mm Tokarev ammunition, it used a forward-sliding barrel as a counterweight for the bolt. The barrel movement was synchronized to the bolt using a pivoting lever instead of more typical gear system.